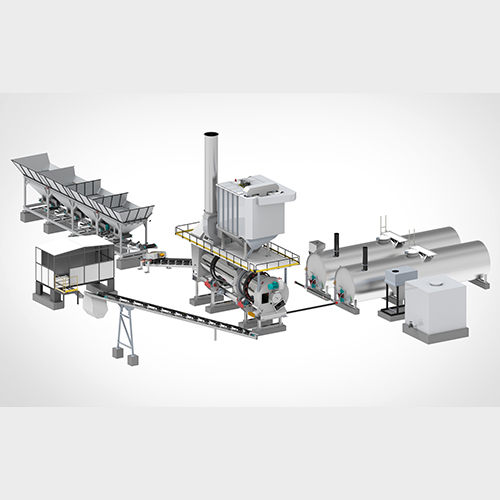

CFD-90 Nilang Counter Flow Drum Mix Plant

Price 6000000 - 6800000 INR/ Ton

CFD-90 Nilang Counter Flow Drum Mix Plant Specification

- Coverage Area

- Wide Area Coverage

- Tank Dimensions (Mm X Mm X Mm)

- 3,000 x 2,000 x 2,500 mm

- Hopper Capacity

- 3.5 m

- Fuel Type

- Diesel/FO

- Temperature

- Up to 160C

- Compressor Type

- Rotary Compressor

- Driven Type

- Electric

- Air Pressure

- 7 bar

- Mount Type

- Stationary

- Tank Material

- Mild Steel

- Working Width

- 2.5 meters

- Noise Level

- < 85 dB(A)

- Hole Size

- Standard

- Type

- Counter Flow Drum Mix Plant

- Material

- Heavy Duty Steel Structure

- Capacity

- 90 TPH (Tons per Hour)

- Computerized

- Yes

- Automatic Grade

- Automatic

- Cooling System

- Advanced Air Cooled System

- Vibration Frequency

- 50 Hz

- Drum Diameter

- 2.0 meters

- Power

- 120 kW

- Size

- Large

- Color

- Blue/Yellow

- Weight

- Approx. 22,000 Kg

- Dimension (L*W*H)

- 18,000 x 3,500 x 4,500 mm

- Dust Collection

- Multi-stage with bag house filter

- Chassis

- Robust I-beam construction

- Control Panel

- Microprocessor-based with remote operation

- Bitumen Weighing

- Fully electronic load cells

- Elevator

- Bucket type with heavy duty chains

- Safety Features

- Emergency stop and multiple alarm systems

- Mixing Type

- Counter-flow continuous mixing

- Feeder System

- Four bin feeder with variable speed drive

- Burner Type

- Automatic pressure jet oil burner

- Power Supply

- 380V, 50Hz, 3-phase

- Aggregate Silo Capacity

- 10 Tons

- Aggregate Screening Capacity

- High efficiency vibrating screen

CFD-90 Nilang Counter Flow Drum Mix Plant Trade Information

- Minimum Order Quantity

- 1 Ton

- Supply Ability

- 4 Tons Per Month

- Delivery Time

- 2-3 Week

About CFD-90 Nilang Counter Flow Drum Mix Plant

CFD-90 Nilang Counter Flow Drum Mix Plant is well known for its user friendly operating system and environment friendly mechanism. This plant is mainly used for producing asphalt at low production charge for its fuel efficient operation. Emission free mechanism of this plant maintains cleanliness of surrounding environment. CFD-90 Nilang Counter Flow Drum Mix Plant comprises of 4/2 hp auxiliary conveyor drive motor, thermo drum drive type friction drive, 5 hp hydraulic power pack etc. This plant can be set up at low labor cost.

Specification

| Auxillary Conveyor drive Motor (HP) | 4/2 HP |

| Brand | Nilang |

| Model Name/Number | CFD-90 |

| No Of Bins Total Storage | 4/40 Ton |

| Country of Origin | Made in India |

| Wire Mesh Size | 45x45 mm |

| Thermo Drum Drive Type | 4 W Friction Drive |

| Slinger Conveyor Belt (mm) | 500x15025 mm (WxL) |

| Pollution Control Filter Area (sqm) | 180 Sqm |

| Over Size Removal Screen Drive Motor (HP) | 3 HP |

| Mineral Filler Tank Capacity (m3) | 1.5 m3 |

| Load Out Conveyor Capacity (tph) | 200 TPH |

| Hydraulic Power Pack(HP) | 5 HP |

| Hot Mix Storage Silo (Ton) | 25/50 Ton |

| Gob Hopper Capacity (Ton) | 1.5 Ton |

| Gathering Conveyor Belt | 600x25600 mm |

| Countinual Plant Capacity at 3% Moisture (tph) | 60-90 TPH |

| Bitumen Tank Capacity (Ton) | 20/30 Ton Horizontal Type, Direct Heating |

| Bin Vibrator | 0.25 HP |

State-of-the-art Control Panel

The CFD-90 is equipped with a microprocessor-based control panel that supports remote operation, allowing users to monitor and manage plant performance from a distance. This advanced interface increases operational efficiency, streamlines troubleshooting, and ensures optimal process control.

Efficient Material Handling and Mixing

Designed for maximum productivity, the plant uses counter-flow continuous mixing, combined with heavy-duty chains on the bucket elevator and high-efficiency vibrating aggregate screens. The integration of electronic load cells for bitumen weighing guarantees precise mixture consistency every cycle.

Superior Safety and Environmental Features

Safety is prioritized through the inclusion of emergency stop buttons and multiple alarm systems. The multi-stage dust collection system, with a bag house filter, minimizes emissions, ensuring a safer working environment and compliance with environmental standards.

FAQ's of CFD-90 Nilang Counter Flow Drum Mix Plant:

Q: How does the CFD-90 Nilang Counter Flow Drum Mix Plant enhance asphalt production efficiency?

A: The plant utilizes counter-flow continuous mixing, a computerized control panel, and fully electronic bitumen weighing to deliver high-quality, consistent asphalt at a capacity of 90 tons per hour. These features collectively streamline the production process and optimize output.Q: What safety features are incorporated into the CFD-90 Drum Mix Plant?

A: This plant includes multiple safety measures such as an emergency stop button, alarms to indicate malfunctions or operational issues, and heavy-duty steel construction for structural integrity, ensuring operator protection and safe on-site operation.Q: When is remote operation of this drum mix plant advantageous?

A: Remote operation is particularly beneficial during large-scale projects that require constant supervision without on-site presence, or when swift adjustments to the production process are needed to maintain consistent product quality.Q: Where can the CFD-90 Drum Mix Plant be effectively installed?

A: This stationary model is well-suited for wide area coverage on major infrastructure sites such as highway construction, airport runways, and urban road expansion, especially where a high production rate is needed.Q: What is the dust management process in the CFD-90 plant?

A: Dust is controlled through a multi-stage collection system equipped with a bag house filter, which captures fine particles and keeps emissions under 85 dB(A), contributing to a safer and environmentally friendly workspace.Q: How is aggregate mixing accuracy ensured in the CFD-90?

A: A high-efficiency vibrating screen grades aggregates precisely before they enter the drum. The four bin feeder with variable speed drive and electronic bitumen weighing ensures the exact proportions in every batch.Q: What benefits does the advanced air-cooled system provide?

A: The advanced air-cooled system ensures that the machinery remains at an optimal operating temperature, enhancing equipment lifespan, reducing maintenance needs, and supporting continuous, reliable plant operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Counter Flow Drum Mix Plant Category

CFD-90 Counter Flow Drum Mix Plant

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Mount Type : Stationary

Vibration Frequency : 5060 Hz

Drum Diameter : 2.2 m

Weight : 34,000 kg

CFD-120 Counter Flow Drum Mix Plant

Price 1500000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Mount Type : Stationary/Skid Mount

Vibration Frequency : High Frequency Vibrator Integrated

Drum Diameter : 2400 mm

Weight : Approx. 28,000 kg

Automatic Counter Flow Drum Mix Plant

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Mount Type : Stationary or Mobile

Vibration Frequency : 50 Hz

Drum Diameter : 1.2 m to 2.2 m

Weight : 15000 kg (approx.)

CFD-120 Nilang Counter Flow Drum Mix Plant

Price 7800000 INR / Ton

Minimum Order Quantity : 1 Ton

Mount Type : Stationary

Vibration Frequency : 50 Hz Hertz (HZ)

Drum Diameter : 2.2 meters Meter (m)

Weight : Approx. 36,000 kg Kilograms (kg)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS