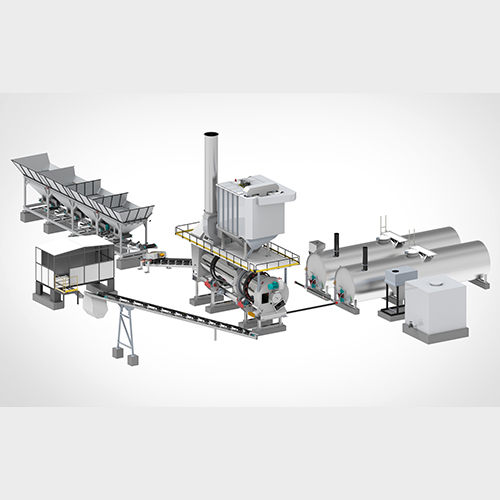

Automatic Counter Flow Drum Mix Plant

Price 1500000 INR/ Unit

Automatic Counter Flow Drum Mix Plant Specification

- Mount Type

- Stationary or Mobile

- Temperature

- 140 - 165 C

- Tank Dimensions (Mm X Mm X Mm)

- 6,000 x 2,400 x 2,600

- Fuel Type

- Diesel / Furnace Oil

- Driven Type

- Electric

- Tank Material

- MS Steel

- Working Width

- 2.4 m

- Coverage Area

- Varies as per configuration

- Hole Size

- Customizable as per requirement

- Hopper Capacity

- 4 x 9 m

- Air Pressure

- 6-8 bar

- Noise Level

- Less than 80 dB

- Compressor Type

- Screw Type

- Type

- Automatic Counter Flow Drum Mix Plant

- Material

- Mild Steel

- Capacity

- 60 to 160 TPH

- Computerized

- Yes

- Automatic Grade

- Automatic

- Cooling System

- Air Cooled

- Vibration Frequency

- 50 Hz

- Drum Diameter

- 1.2 m to 2.2 m

- Power

- 105 kW

- Size

- Medium to Large

- Color

- Yellow & Grey

- Weight

- 15000 kg (approx.)

- Dimension (L*W*H)

- 12,000 mm x 2,400 mm x 4,400 mm

Automatic Counter Flow Drum Mix Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 15 Days

About Automatic Counter Flow Drum Mix Plant

Automatic Counter Flow Drum Mix Plant we offer is known as a highly efficient heat transfer system. It has been made to maximize the heat transfer of from hot gases. It is made to deal with the hot aggregates and allows for efficient operation. This is a high efficiency plant, accessible with many features. Automatic Counter Flow Drum Mix Plant is accessible with advanced heat transfer technology and has outstanding operation. This is made from strong and robust materials.

Specification

| Auxillary Conveyor drive Motor (HP) | 4/3 HP |

| Country of Origin | Made in India |

| Wire Mesh Size | 45x45 mm |

| Thermo Drum Unit Dryer (mm) | 7500x1800 mm |

| Thermo Drum Unit | Cylindrical,Inclined Counter Flow |

| Thermo Drum Fuels | Standard Burner For LDO, Diesel |

| Thermo Drum Drive Type | 4 W Friction Drive |

| Thermo Drum Drive Motor (HP) | 40 HP |

| Thermo Drum Burner | 10 (Long Nose Burner) |

| Slinger Conveyor Belt (mm) | 500x15025 mm (WxL) |

| Pollution Control Filter Area (sqm) | 180 Sqm |

| Over Size Removal Screen Drive Motor (HP) | 3 HP |

| No. Of Bins/ Capacity (Ton) | 4/50 Ton |

| Model No | CFD-120 |

| Mineral Filler Tank Capacity (m3) | 1.5 m3 |

| Load Out Conveyor Capacity (tph) | 200 TPH |

| Hot Mix Storage Silo (Ton) | 25/50 Ton |

| Gob Hopper Capacity (Ton) | 1.5 Ton |

| Gathering Conveyor Drive Motor | 5 HP |

| Gathering Conveyor Belt | 600x29600 mm |

| Feeding Capacity | 140 TPH |

| Countinual Plant Capacity at 3% Moisture (tph) | 90-120 TPH |

| Conveyor Drive Motor (HP) | 5 HP |

| Bitumen Tank Capacity | 20/30 Ton Horizontal Type, Direct Heating |

| Bin Vibrator | 0.25 HP |

Advanced Automation and Control

Equipped with a PLC-based automated control panel, the plant ensures meticulous monitoring and adjustment of each parameter. The computerized system provides precise aggregate metering through individual load cells, enhancing mix accuracy and consistency throughout production cycles.

Environmental Compliance and Efficient Dust Collection

This mix plant integrates a multi cyclone dust collection system combined with a high-efficiency bag filter, minimizing exhaust emissions and maintaining compliance with pollution standards. Operators benefit from a cleaner working environment and reduced ecological impact, facilitating safe and responsible operation.

Mobility and Flexible Configuration

Available on skid or wheel-mounted setups, the plant offers versatility for easy relocation between sites or fixed installations. You can select optional hot mix storage silos up to 50 tons and customize hopper capacity for project-specific requirements, making it adaptable for diverse job sites across India.

FAQs of Automatic Counter Flow Drum Mix Plant:

Q: How does the automatic control panel improve the efficiency of the drum mix plant?

A: The fully automatic, PLC-based control panel allows operators to monitor and manage all functions precisely, optimizing mixing cycles, regulating temperatures, and synchronizing feed rates. This results in consistent quality and reduced operational errors, enhancing overall productivity.Q: What is the process of aggregate metering in this drum mix plant?

A: Aggregate metering is done through individual load cells mounted on each feeder bin. These sensors provide exact measurements, ensuring proper proportioning of materials for efficient mixing and superior hot mix quality.Q: When can onsite commissioning and training be availed?

A: Onsite commissioning and training are available after installation. The manufacturer or suppliers technical team schedules and performs setup alongside hands-on training to ensure your staff can operate and maintain the plant confidently and safely.Q: Where can this drum mix plant be installed?

A: The plant is suitable for a wide range of locations, as it can be configured in stationary setups or mobile units for on-site movement. Its adaptable size makes it ideal for medium to large projects across varied construction sites in India.Q: What are the advantages of the multi cyclone dust collection system with bag filter?

A: This dual system efficiently captures dust and particulate emissions generated during production, ensuring compliance with pollution norms and creating a safer, healthier workplace for operators.Q: How is the hot mix stored and what are the silo options?

A: Hot mix can be stored in an optional silo with a capacity of up to 50 tons. This feature enables batch storage for continuous operations, preventing delays and facilitating delivery flexibility during large-scale road projects.Q: What benefits does the fully automatic oil/gas burner offer?

A: The automatic burner provides precise temperature control within the drum, ensuring uniform heating. Users can select between diesel and furnace oil, optimizing fuel efficiency and reducing maintenance while achieving the required mixture temperatures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Counter Flow Drum Mix Plant Category

CFD-90 Nilang Counter Flow Drum Mix Plant

Price 6000000 - 6800000 INR / Ton

Minimum Order Quantity : 1 Ton

Material : Heavy Duty Steel Structure

Automatic Grade : Automatic

Compressor Type : Rotary Compressor

Noise Level : < 85 dB(A)

CFD-90 Counter Flow Drum Mix Plant

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Automatic Grade : Automatic

Compressor Type : Screw Type

Noise Level : < 85 dB

CFD-120 Counter Flow Drum Mix Plant

Price 1500000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Material : Steel / Heavy Duty Metal Construction

Automatic Grade : Automatic

Compressor Type : Rotary Screw Compressor

Noise Level : < 80 dB

CFD-120 Nilang Counter Flow Drum Mix Plant

Minimum Order Quantity : 1 Ton

Material : High Grade Steel

Automatic Grade : Automatic

Compressor Type : Rotary Screw

Noise Level : < 80 dB

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS