CFD-120 Nilang Counter Flow Drum Mix Plant

CFD-120 Nilang Counter Flow Drum Mix Plant Specification

- Hole Size

- 60 mm

- Mount Type

- Stationary

- Fuel Type

- Diesel/Oil

- Noise Level

- < 80 dB

- Tank Dimensions (Mm X Mm X Mm)

- 4000 x 3000 x 3500

- Tank Material

- Steel with Heat Insulation

- Working Width

- 3.0 meters

- Driven Type

- Electric

- Air Pressure

- 7 bar

- Compressor Type

- Rotary Screw

- Hopper Capacity

- 1500 kg

- Coverage Area

- Up to 120 sq.m/hr

- Temperature

- Up to 160C

- Type

- Counter Flow Drum Mix Plant

- Material

- High Grade Steel

- Capacity

- 120 TPH

- Computerized

- Yes

- Automatic Grade

- Automatic

- Cooling System

- Advanced Air Cooling

- Vibration Frequency

- 50 Hz

- Drum Diameter

- 2.2 meters

- Power

- 120 kW

- Size

- Standard, customizable

- Color

- Nilang Yellow & Black

- Weight

- Approx. 36,000 kg

- Dimension (L*W*H)

- 20m x 3.5m x 4.5m

CFD-120 Nilang Counter Flow Drum Mix Plant Trade Information

- Minimum Order Quantity

- 1 Ton

- Supply Ability

- 4 Tons Per Month

- Delivery Time

- 2-3 Week

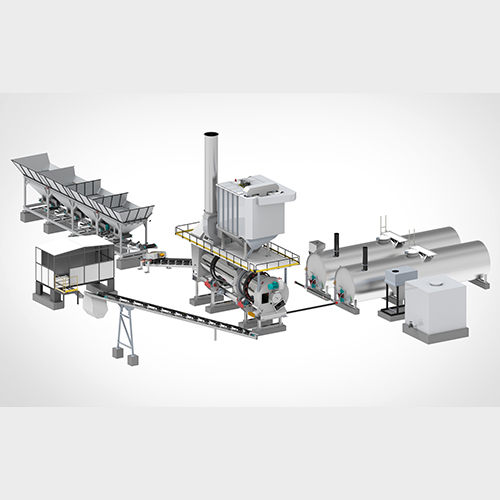

About CFD-120 Nilang Counter Flow Drum Mix Plant

CFD-120 Nilang Counter Flow Drum Mix Plant is well known for its low production cost and high performance. This plant consists of cylindrical thermo drum unit with inclined counter flow based operation, 40 hp thermo drum drive motor, mineral filter tank of 1.5 m3 capacity and so on. Gathering conveyor belt of this plant is driven by 5 hp motor. CFD-120 Nilang Counter Flow Drum Mix Plant has horizontal type bitumen tank with maximum 30 ton storage capacity. Feeding capacity of this plant is 140 TPH.

Specification

|

Auxillary Conveyor drive Motor (HP) |

4/3 HP |

|

Country of Origin |

Made in India |

|

Wire Mesh Size |

45x45 mm |

|

Thermo Drum Unit Dryer (mm) |

7500x1800 mm |

|

Thermo Drum Unit |

Cylindrical,Inclined Counter Flow |

|

Thermo Drum Fuels |

Standard Burner For LDO, Diesel |

|

Thermo Drum Drive Type |

4 W Friction Drive |

|

Thermo Drum Drive Motor (HP) |

40 HP |

|

Thermo Drum Burner |

10 (Long Nose Burner) |

|

Slinger Conveyor Belt (mm) |

500x15025 mm (WxL) |

|

Pollution Control Filter Area (sqm) |

180 Sqm |

|

Over Size Removal Screen Drive Motor (HP) |

3 HP |

|

No. Of Bins/ Capacity (Ton) |

4/50 Ton |

|

Model No |

CFD-120 |

|

Mineral Filler Tank Capacity (m3) |

1.5 m3 |

|

Load Out Conveyor Capacity (tph) |

200 TPH |

|

Hot Mix Storage Silo (Ton) |

25/50 Ton |

|

Gob Hopper Capacity (Ton) |

1.5 Ton |

|

Gathering Conveyor Drive Motor |

5 HP |

|

Gathering Conveyor Belt |

600x29600 mm |

|

Feeding Capacity |

140 TPH |

|

Countinual Plant Capacity at 3% Moisture (tph) |

90-120 TPH |

|

Conveyor Drive Motor (HP) |

5 HP |

|

Bitumen Tank Capacity |

20/30 Ton Horizontal Type, Direct Heating |

|

Bin Vibrator |

0.25 HP |

Advanced Counter Flow Technology

The CFD-120 Nilang Drum Mix Plant incorporates advanced Counter Flow Technology for aggregate heating, maximizing thermal efficiency while minimizing emissions. This technology ensures uniform temperature distribution and optimal bitumen coating, resulting in superior asphalt quality for large-scale road works.

Automated Control for Seamless Operation

With a fully PLC-based touch screen control panel, the plant offers complete automation of blending, metering, and monitoring processes. Operators benefit from real-time data, customizable settings, and user-friendly controls, all housed within a fully air-conditioned control cabin for enhanced comfort and productivity.

Superior Environmental Compliance

Equipped with a multi-stage wet and dry scrubber system, the CFD-120 meets stringent pollution control norms. This comprehensive dust collection mechanism ensures cleaner emissions and safer working conditions, helping contractors adhere to local environmental standards effortlessly.

FAQs of CFD-120 Nilang Counter Flow Drum Mix Plant:

Q: How does the counter flow technology work in the CFD-120 Nilang Drum Mix Plant?

A: The counter flow technology in the CFD-120 Drum Mix Plant heats aggregates by passing them in the opposite direction to the hot gases. This design maximizes heat transfer, promoting efficient mixing and homogeneous asphalt output while reducing fuel consumption and emissions.Q: What are the main benefits of the automated PLC-based control panel?

A: The PLC-based touch screen control panel automates most plant processes, offering real-time monitoring, precise adjustment of mix parameters, rapid troubleshooting, and minimized human error. This leads to consistent asphalt quality, improved productivity, and enhanced safety.Q: Where is the CFD-120 typically installed and can it be made mobile?

A: The CFD-120 is usually installed as a stationary unit, ideal for fixed-site projects and large-scale asphalt production. However, it offers an optional mobile chassis, allowing for relocation when project requirements demand flexibility or multiple sites.Q: What environmental standards does the dust collection system meet?

A: The multi-stage wet and dry scrubber dust collection system is engineered to comply with stringent pollution control norms in India. This advanced system captures particulates and reduces emissions, ensuring minimal environmental impact during continuous operation.Q: How is bitumen supply managed in this drum mix plant?

A: Bitumen is supplied automatically through a fully metered, fully insulated system. This ensures accurate dosing, efficient heat retention, and prevents material loss, contributing to consistent asphalt quality and operational efficiency.Q: What is the typical usage process for the CFD-120?

A: To operate, aggregates are fed with variable speed drives, heated via counter flow in the drum, mixed continuously with metered bitumen, and monitored via the automated control panel. The finished mix is discharged for immediate use, enabling high output with minimal manual intervention.Q: What safety measures are incorporated in the CFD-120 plant?

A: The plant is equipped with emergency stop systems, safety locks, fully insulated tanks, and an air-conditioned control cabin. These features protect both operators and equipment, ensuring safe, reliable, and comfortable operation in demanding site environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Counter Flow Drum Mix Plant Category

CFD-90 Nilang Counter Flow Drum Mix Plant

Price 6000000 - 6800000 INR / Ton

Minimum Order Quantity : 1 Ton

Mount Type : Stationary

Weight : Approx. 22,000 Kg

Hole Size : Standard

Computerized : Yes

Automatic Counter Flow Drum Mix Plant

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Mount Type : Stationary or Mobile

Weight : 15000 kg (approx.)

Hole Size : Customizable as per requirement

Computerized : Yes

CFD-90 Counter Flow Drum Mix Plant

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Mount Type : Stationary

Weight : 34,000 kg

Hole Size : Custom as per requirement

Computerized : Yes

CFD-120 Counter Flow Drum Mix Plant

Price 1500000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Mount Type : Stationary/Skid Mount

Weight : Approx. 28,000 kg

Hole Size : Customizable as per design

Computerized : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS